|

| Carriage pinion, eccentric, etc. |

|

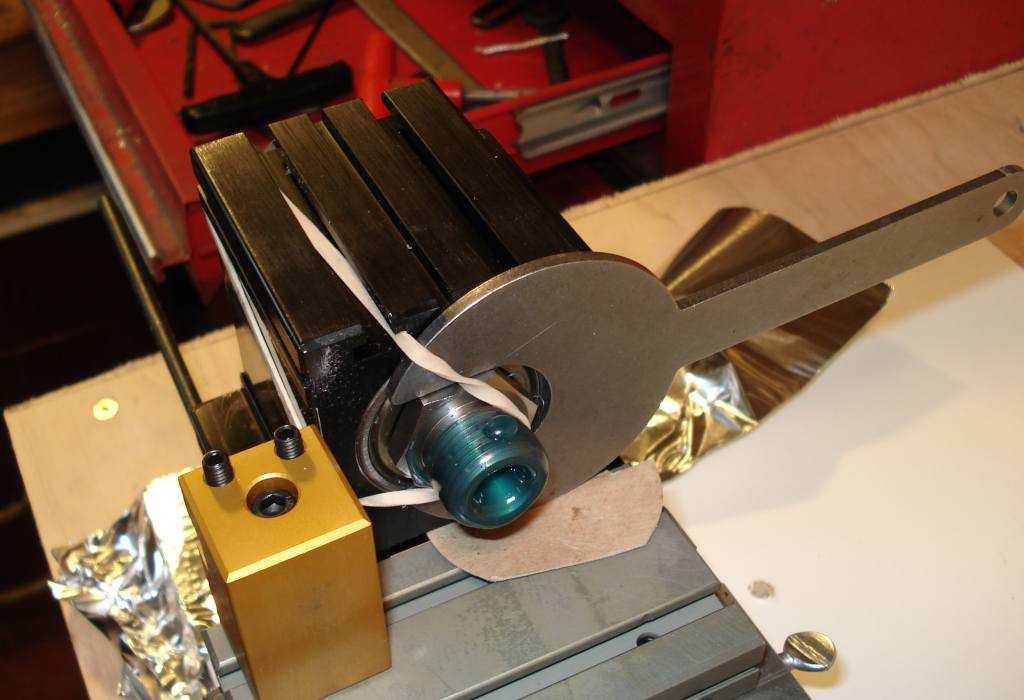

| The eccentric. |

|

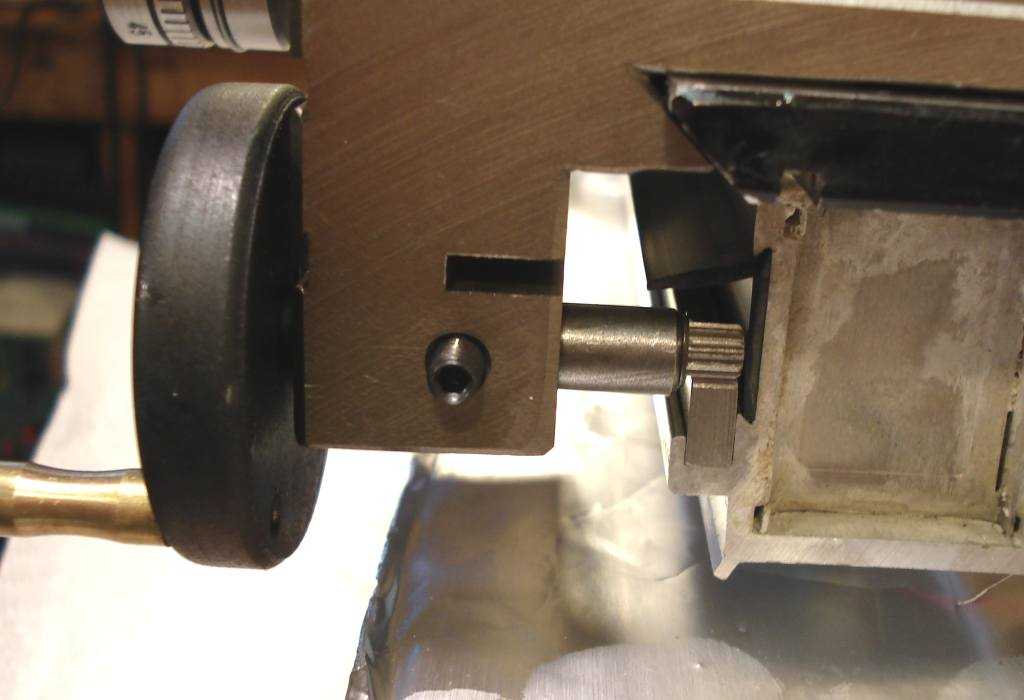

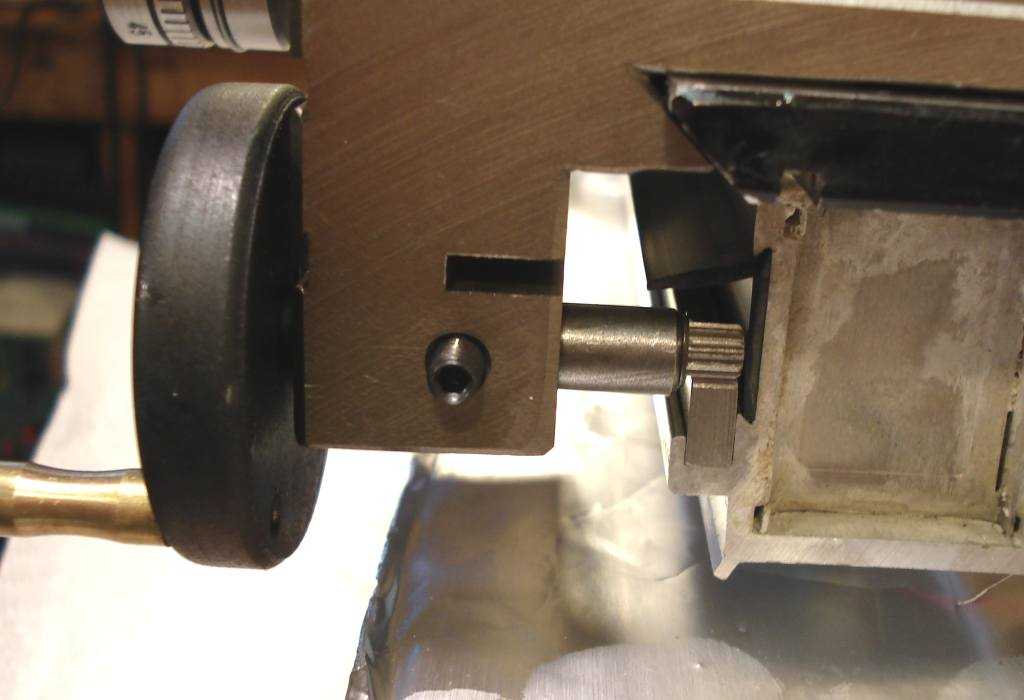

| Insert the eccentric bushing in the carriage. Make sure the thick side is against the locking screw. |

|

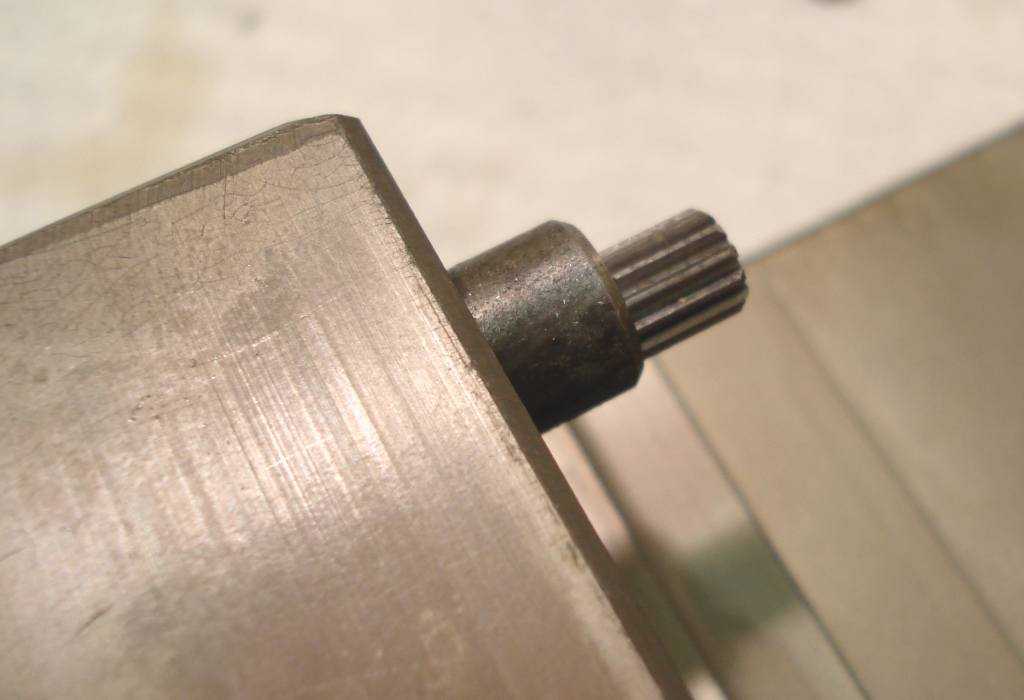

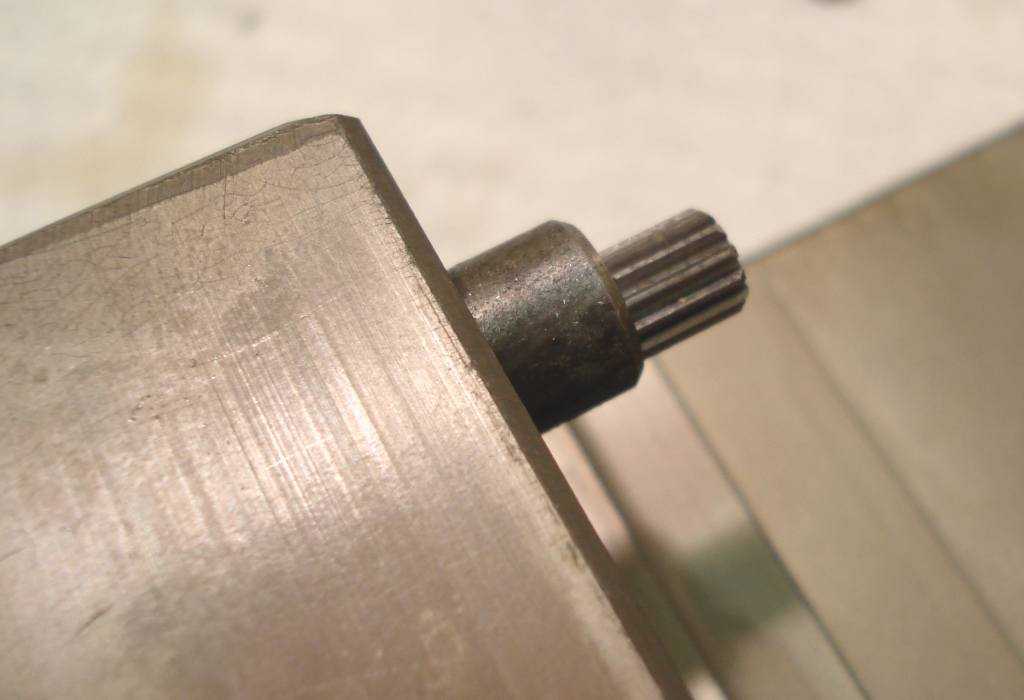

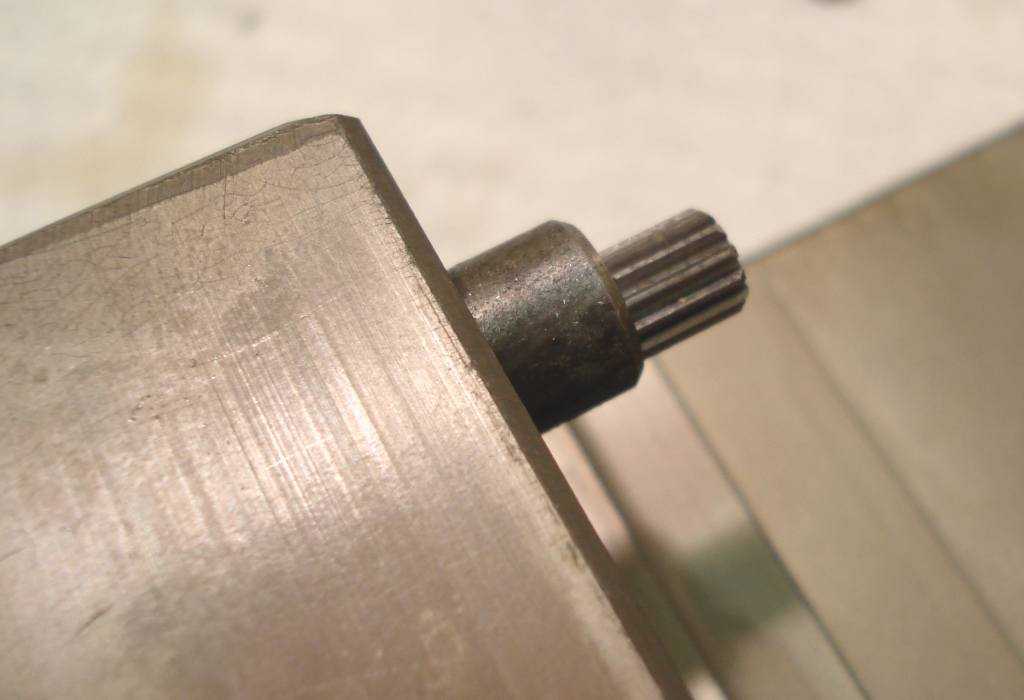

| The pinion sticks out the bushing. |

|

| For

some reason the groove that was used for the c-clip doesn't extend past

the bushing anymore. I think they have a ton of the pinions with this

old feature. |

|

| The

c-clip slides on (it takes a while to line it up and get it on, be

patient...) but doesn't hit the groove. I usually leave the c-clip off

anyway as it makes cleaning easier. |

|

| How everything should look. |

|

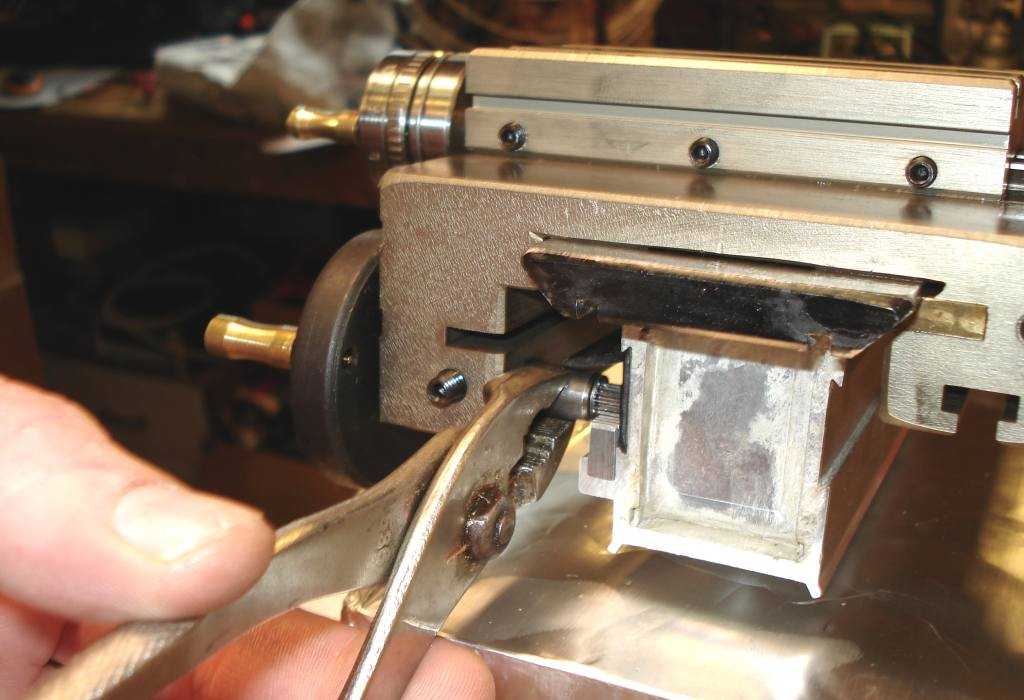

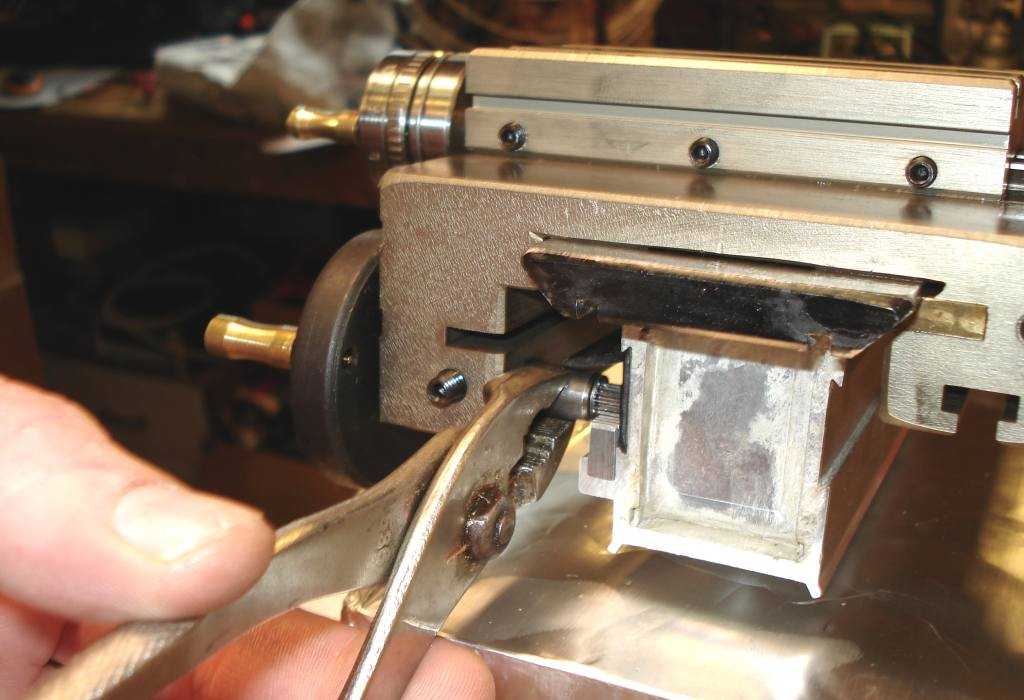

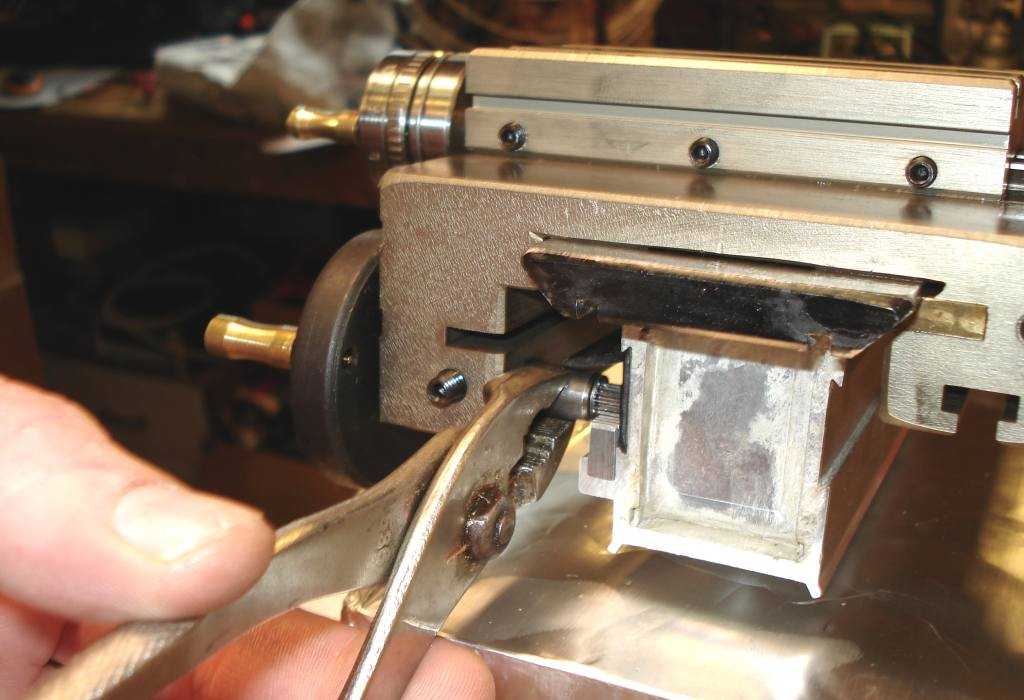

| Adjust the eccentric so that the pinion grabs a piece of paper between it and the rack. |

|

| I used pliers, gently(!) |

|

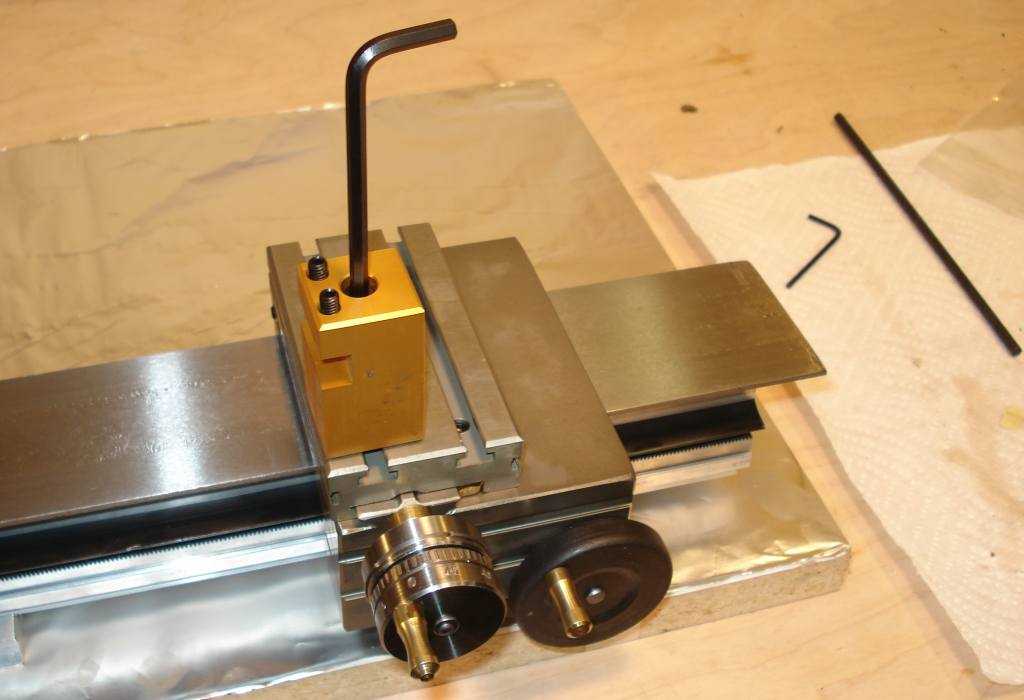

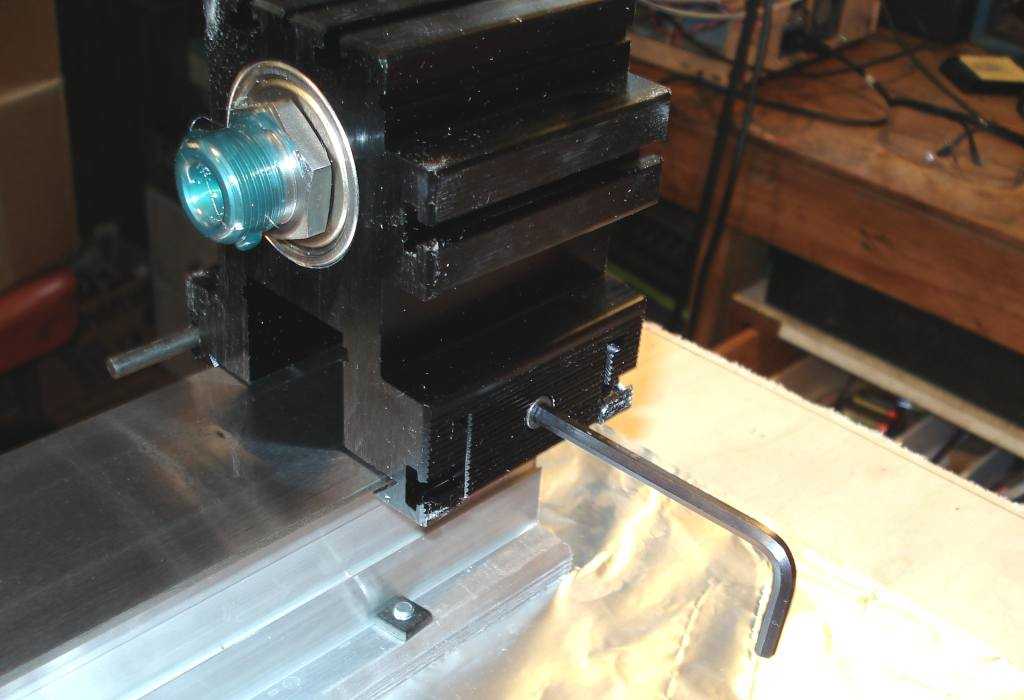

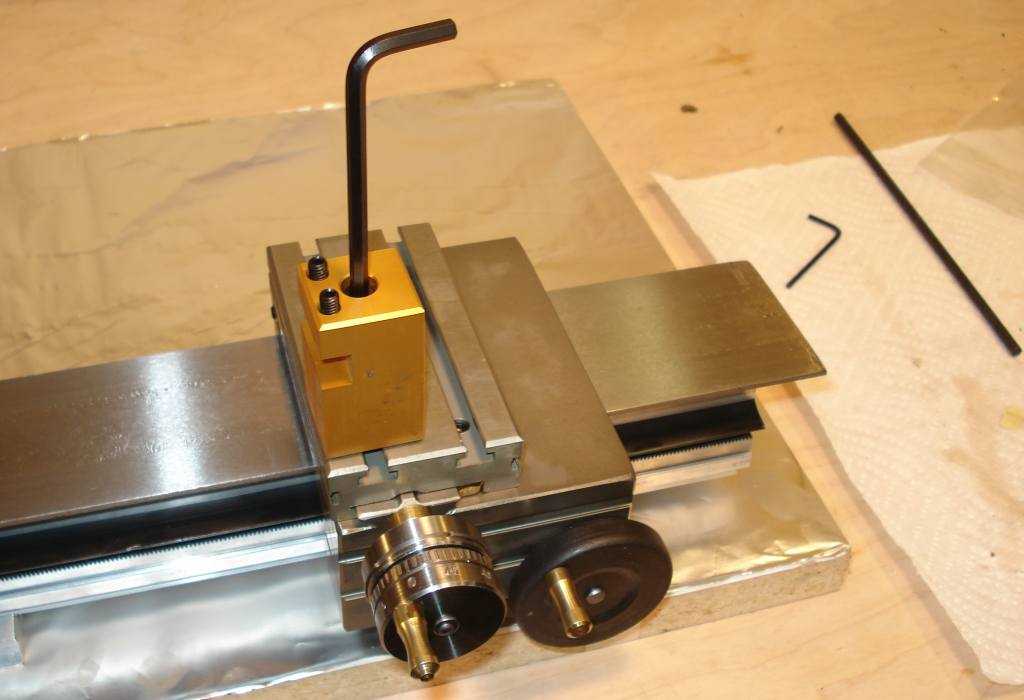

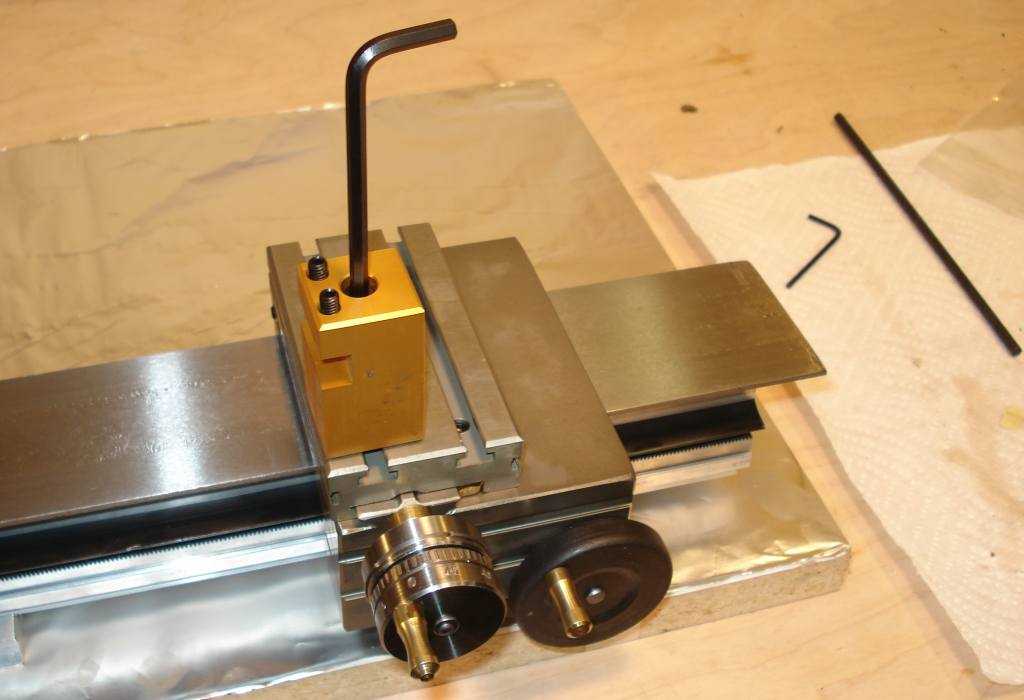

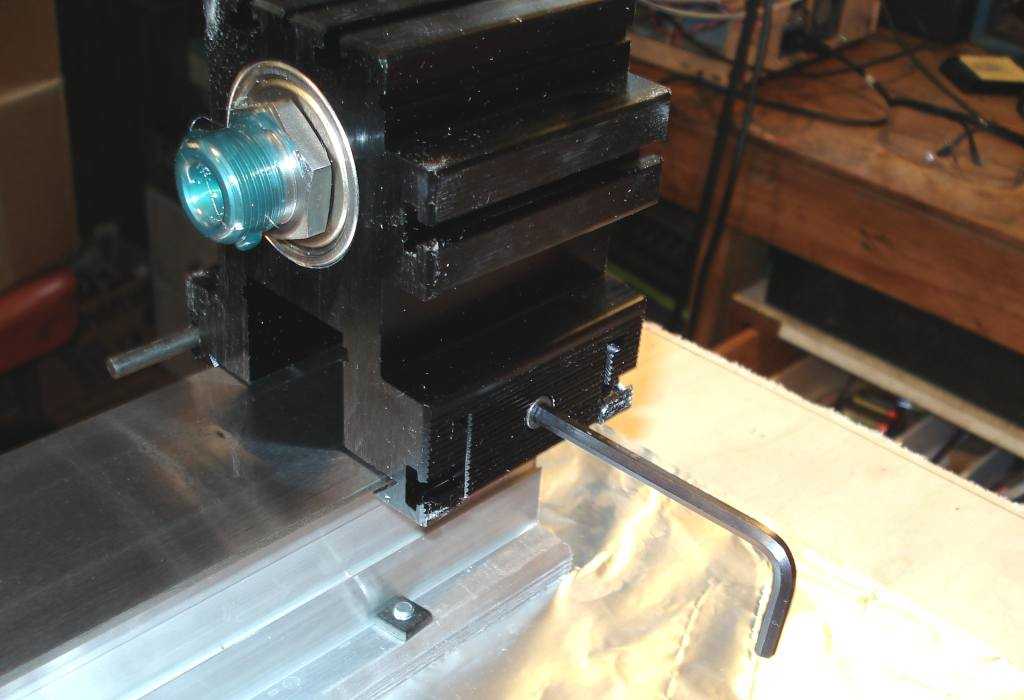

| That's how the toolpost mounts... |

|

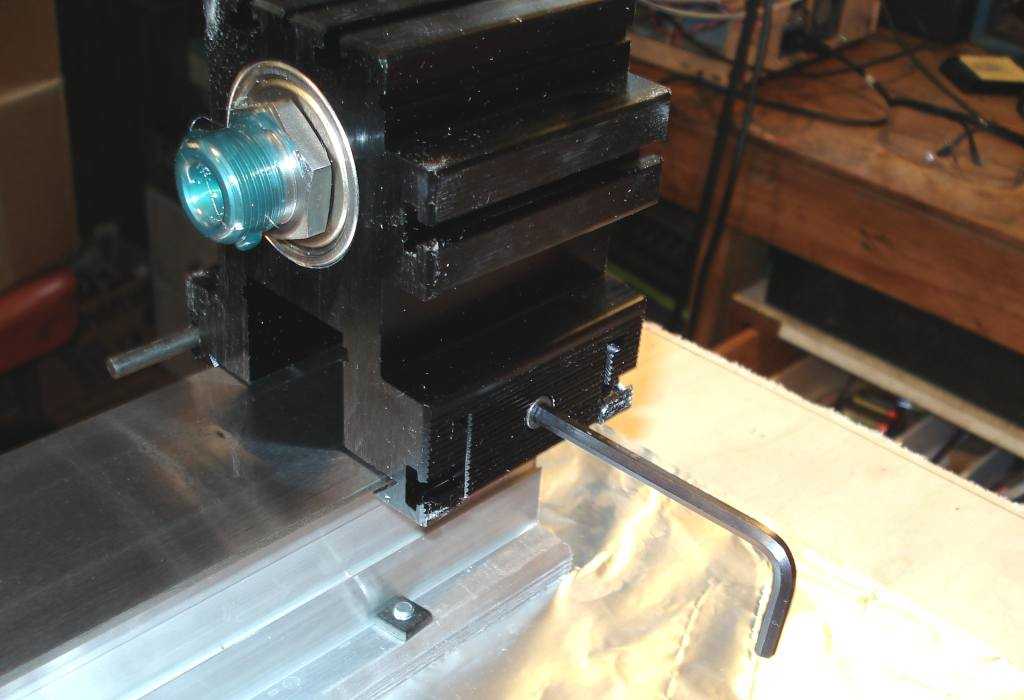

| Depth stop in place on the headstock. |

|

| One screw through the clamping shoe locks the headstock in place. |

|

| You may need to debur the inside of the headstock pulley where the setscrew comes through. |

|

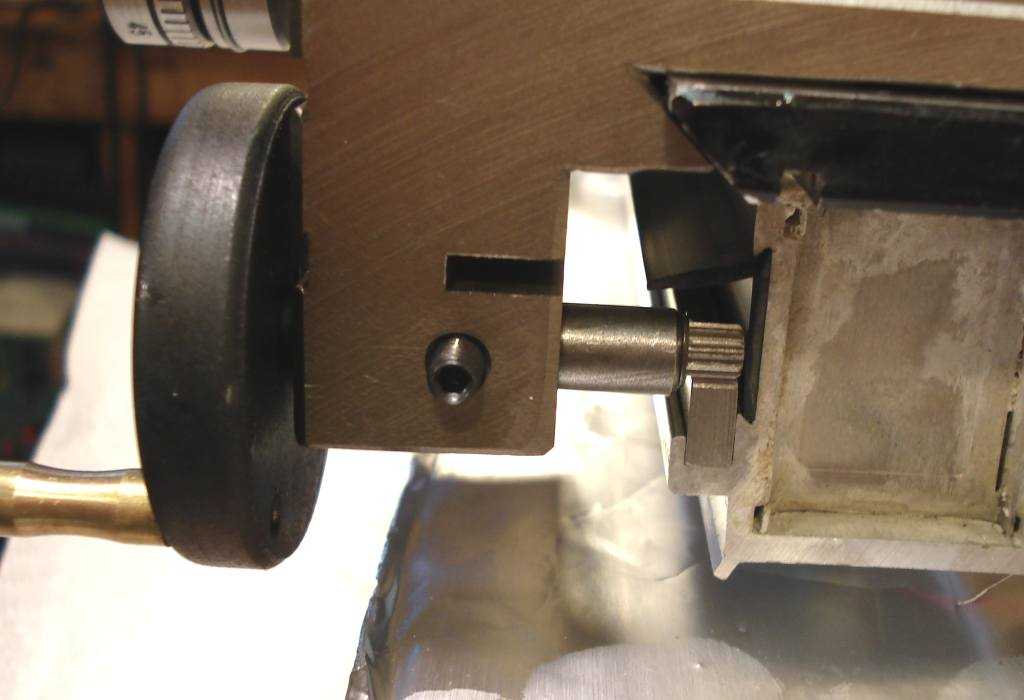

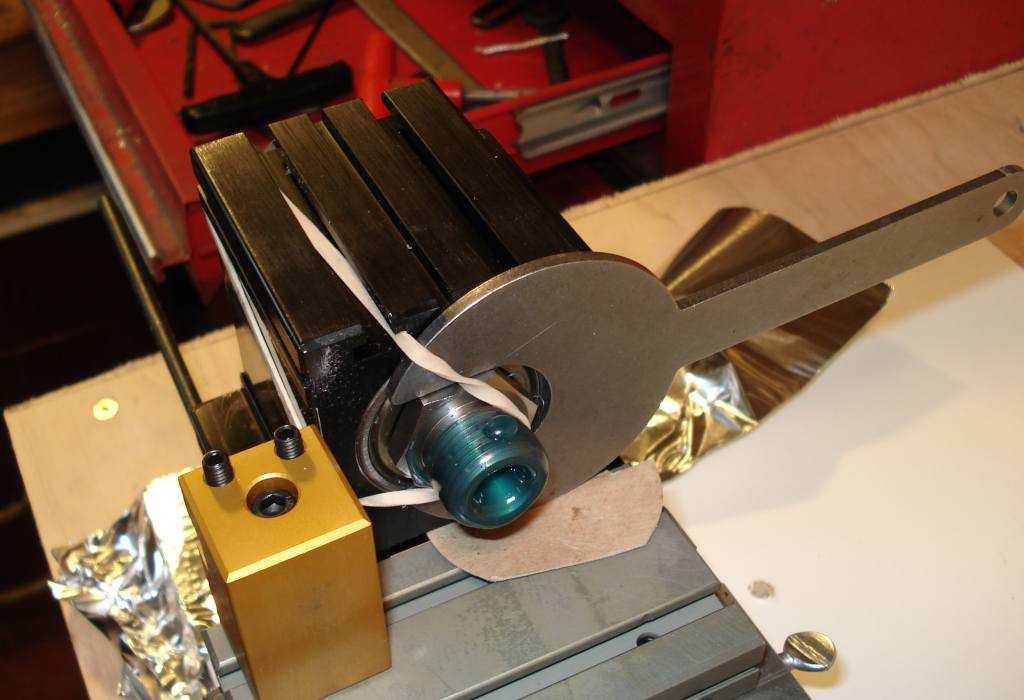

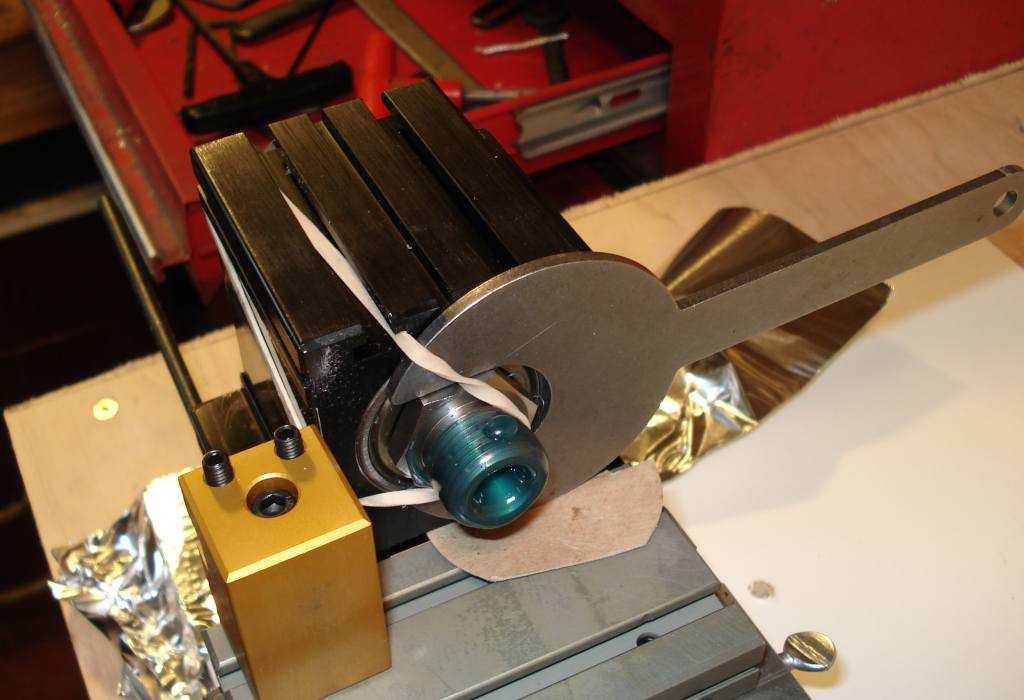

| One way to immobilize the spindle. |

|

| So I can file a flat on the headstock shaft. Not mandatory but it makes it easier to remove the pulley later. |

|

| Flat. |

|

| Tightening the pulley setscrew. That's it! |