How do I make a square hole in (aluminum) sheet metal? 2nd

edition 2019.

By Nick Carter

Why

would you want to make a square or rectangular hole in aluminum sheet

metal? The short answer is that engineers are perverse, thus they

design components with square or rectangular dimensions, which require

you to mount them in a square or rectangular hole. You may also want to

keep a component that slides in or mounts on a hole from rotating, make

a picture frame, or perhaps you just happen to have a round peg that

seems lonely. Look around at all the square and rectangular openings on

your PC or do a Google search for “square hole”, you’ll understand.

The 2019 answer, for me at least, is analog modular synthesizer DIY.

I've

updated this article a bit from the version originally published by

Make: Magazine as their website now seems to be slowly

disintegrating.

Here are some methods depending on the

tools you have and the size of the square hole and the thickness of the

sheet metal.

The first step for all these methods is to

mark where on the sheet you want your square hole, and sometimes the

center of the square. Use either a fine tipped sharpie or a metal

scriber depending on your tolerances. In the pictures I have covered

the sheet metal with layout dye which is thin ink that you can brush or

spray on metal to make a scribed line stand out.

1) If the

aluminum is thin (pop can thickness) you can just pierce the metal with

scissors and cut out the square. For slightly thicker metal you can use

sheet metal shears to cut out the inside of the hole.

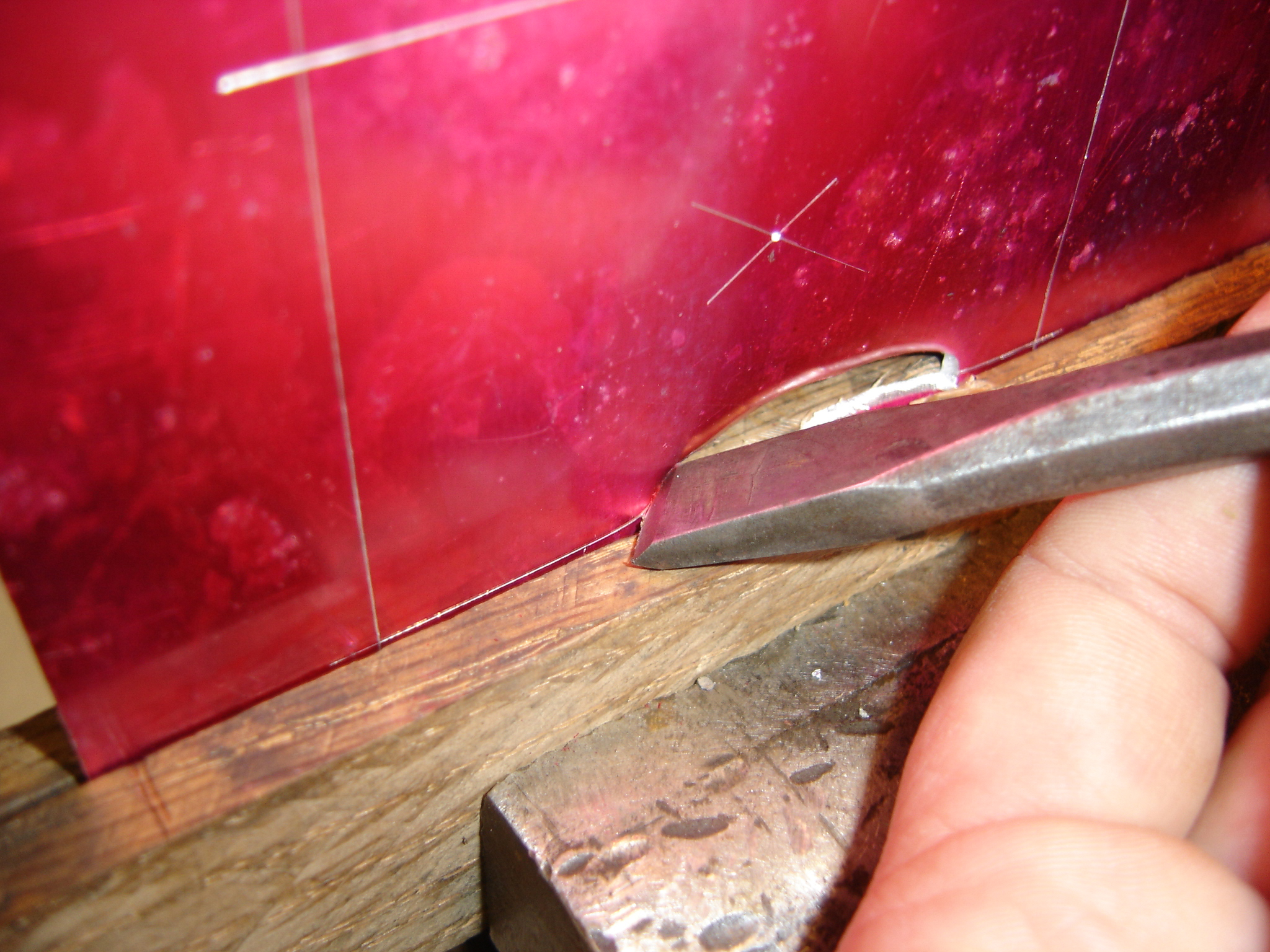

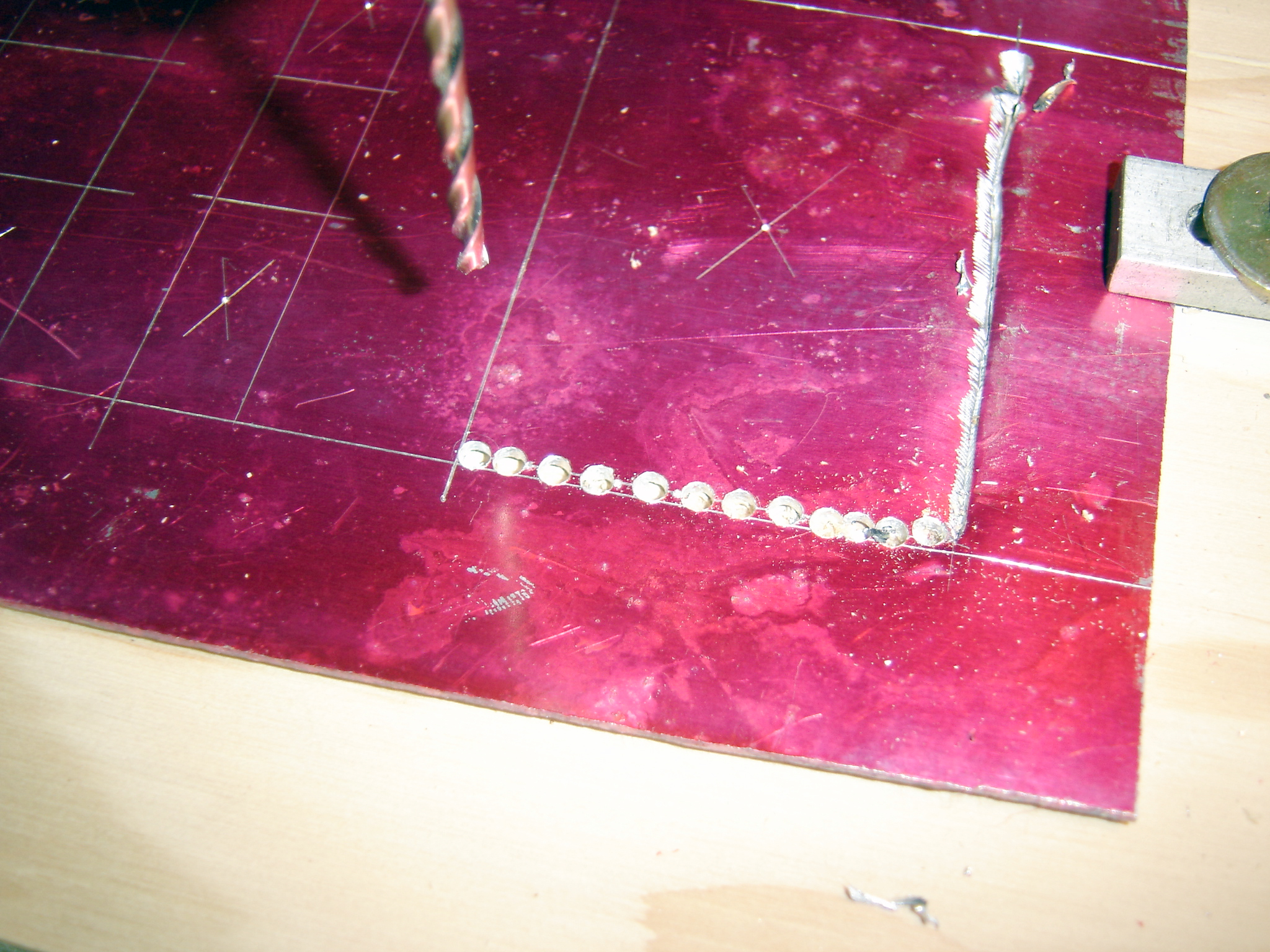

2) You can

shear the hole with a hammer and metal cutting chisel (don't ruin your

wood chisels!). Place the work in a vise with the edge to be cut just

slightly above the vise jaws and hammer the chisel into the work so the

edge of the chisel is parallel to the edge, and held horizontal at

about a 45 degree angle out from the sheet. Do each edge and the square

should pop out. Deburr the edges with a file, and hammer any distortion

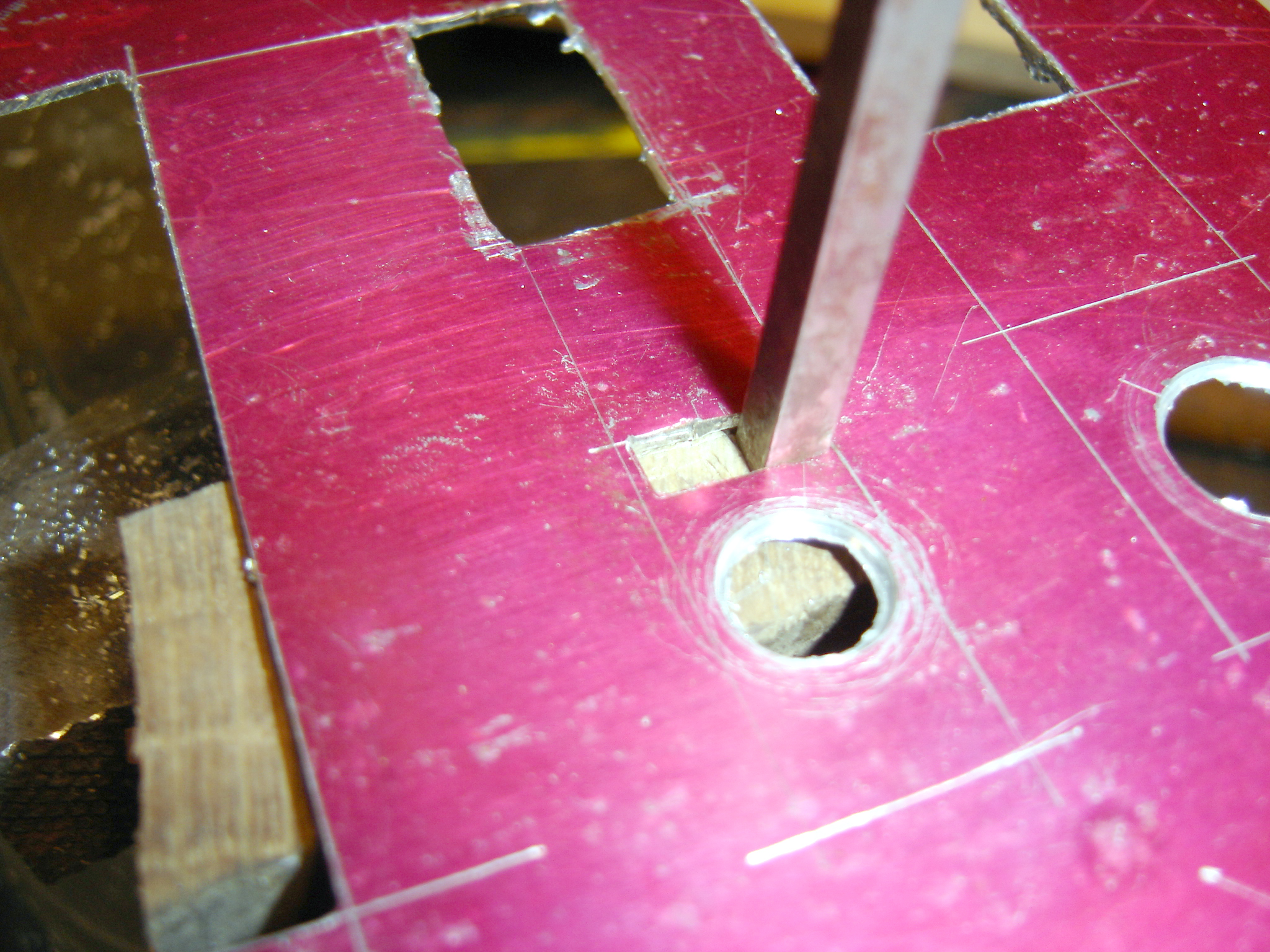

flat. Picture #1 shows a chisel cutting one edge of a hole. Notice that

you do get a rather large burr on the cut edge with this method.

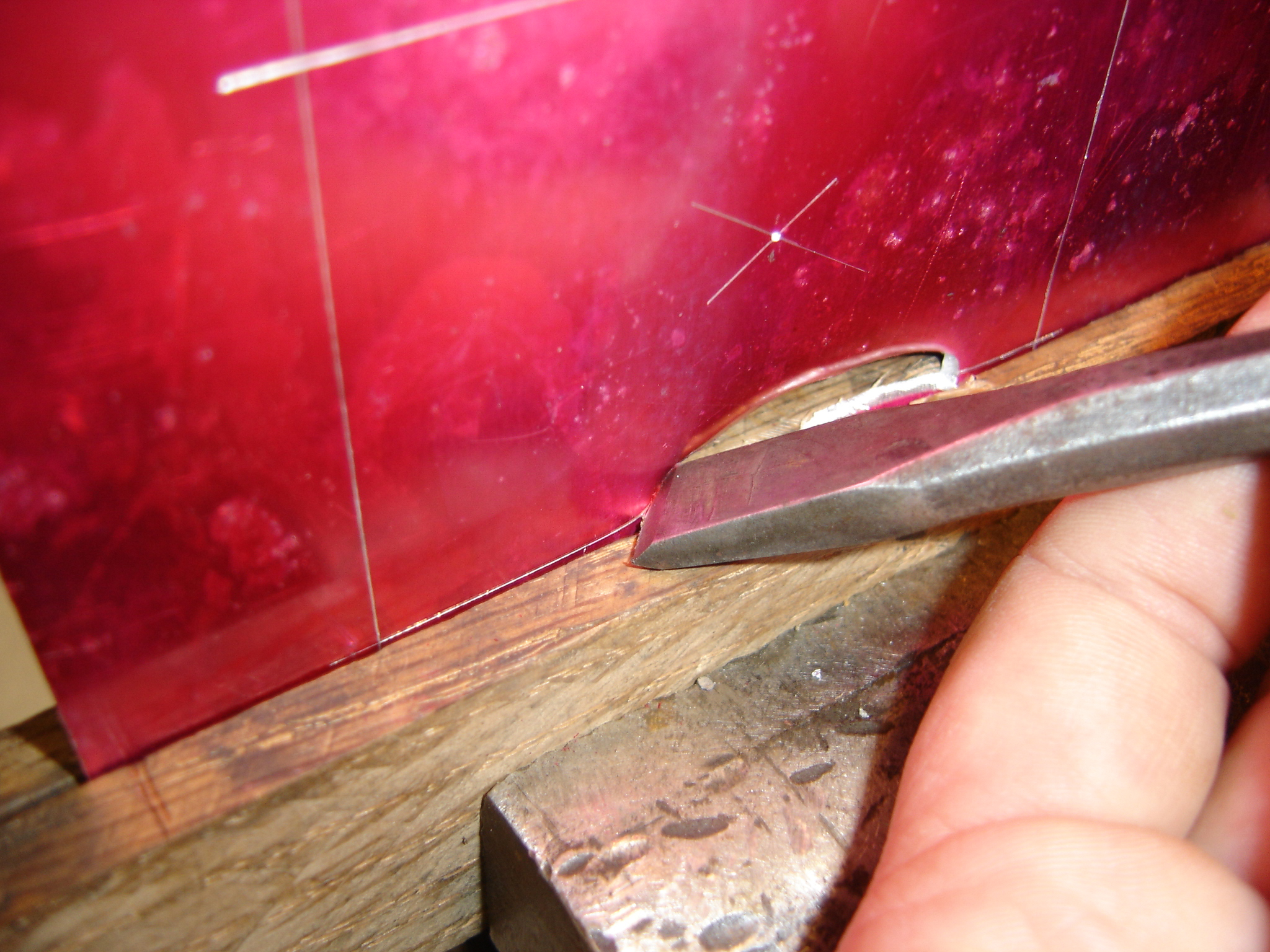

3)

Drill a series of small holes around the periphery of the hole, inside

the edges, and use a shear, saw or chisel to remove the waste, and

again file the edges. This is a good technique on larger holes. Picture

#2 shows a row of holes along the edge of a hole.

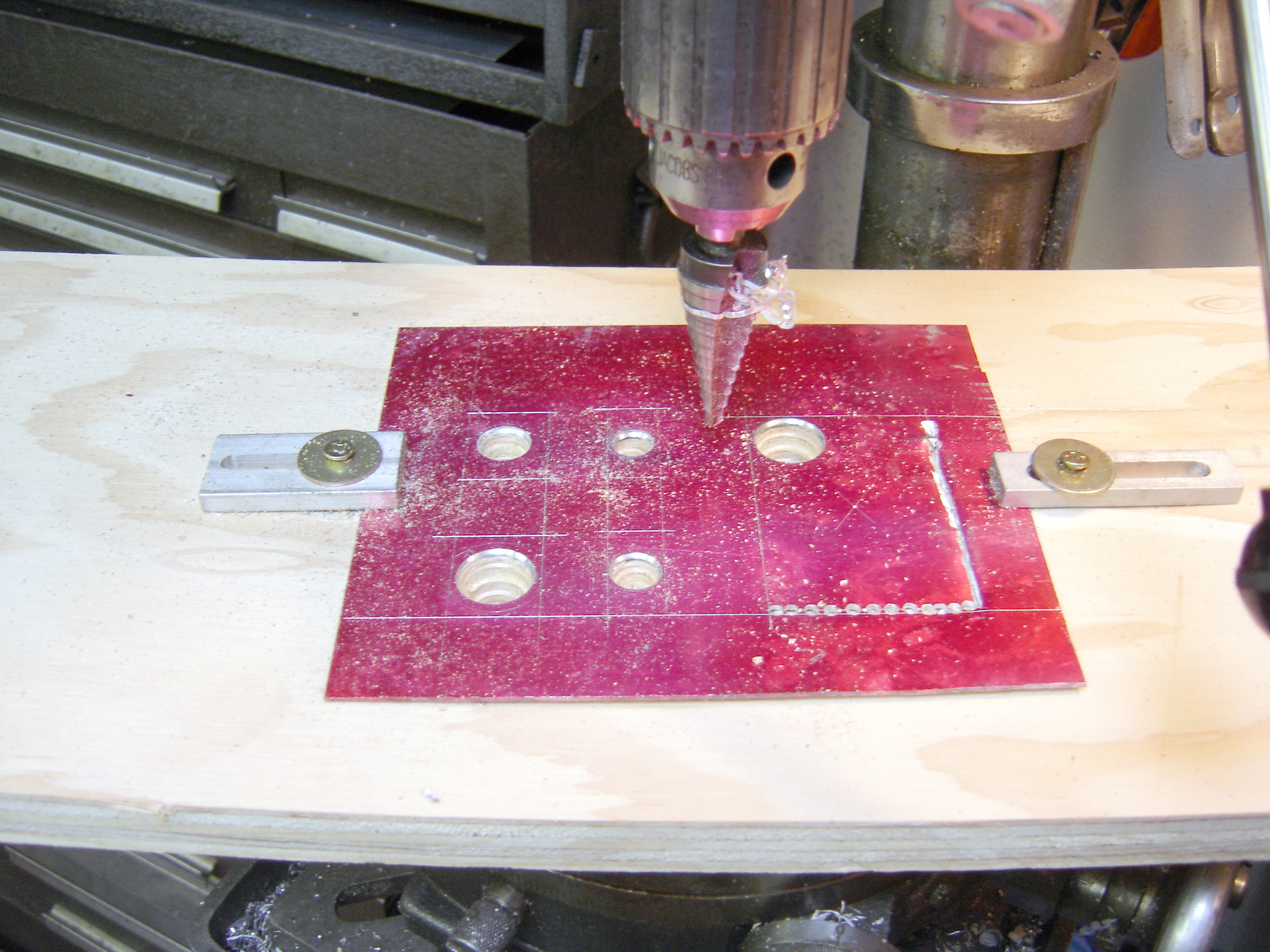

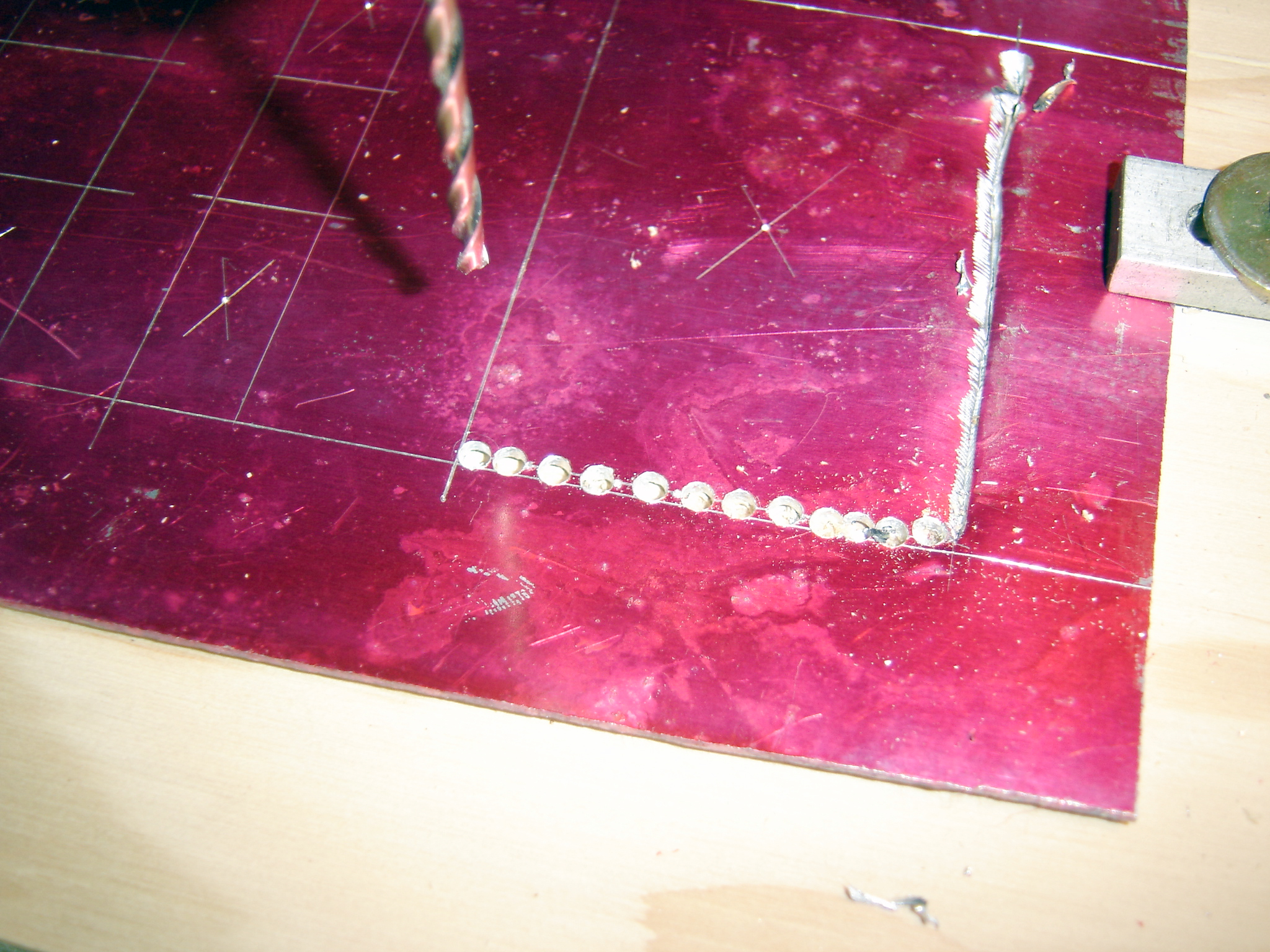

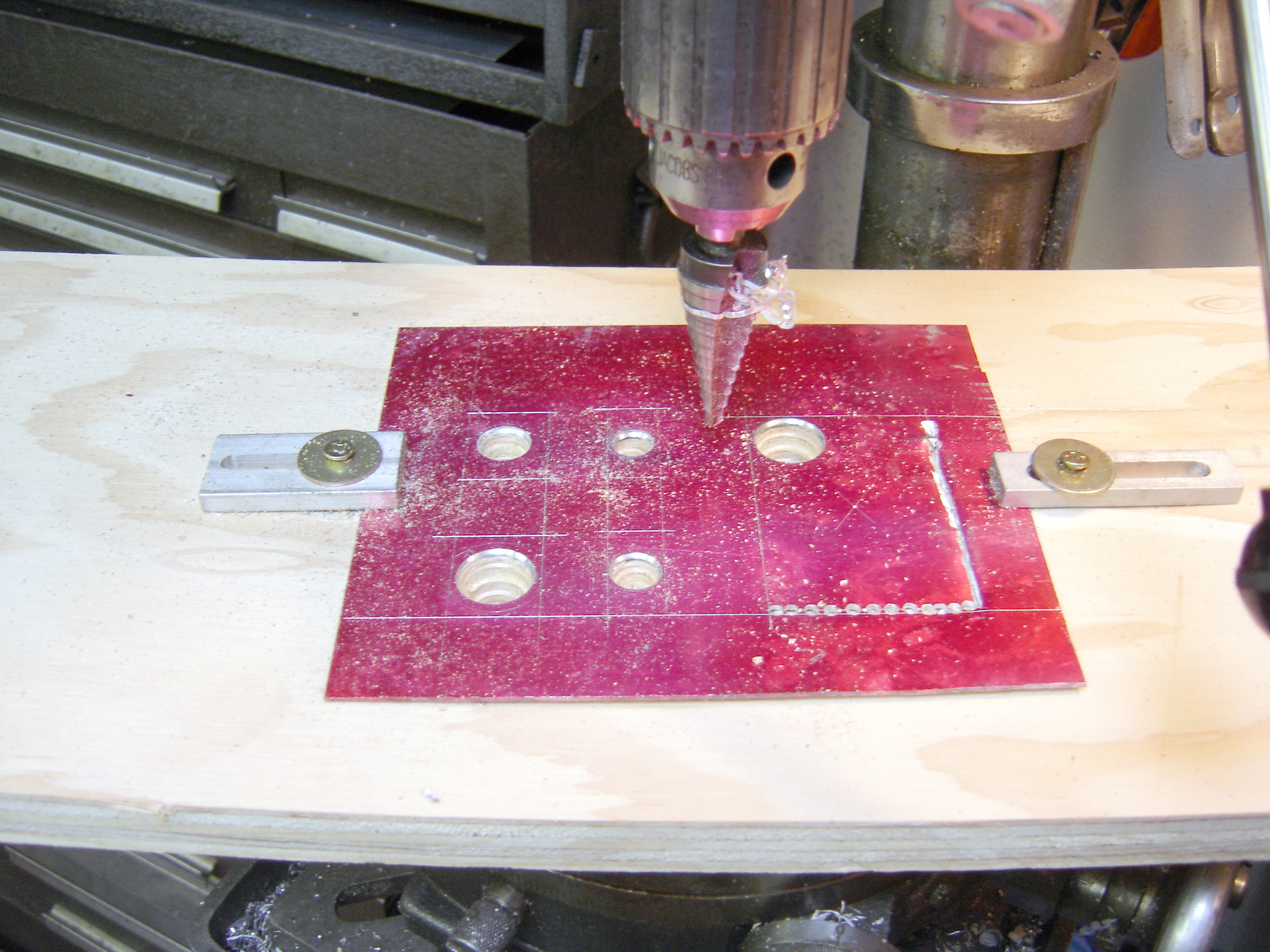

4)

Drill out the center of the hole using a "Unibit" sheet metal step

drill and file the edges square. A power file (air or electric) or a

"die filer" could be used to advantage on thicker metal. Picture #3

shows a number of holes drilled with the Unibit chucked up on the drill

press, notice the sheet metal has been mounted to a piece of plywood.

Never, ever hold sheet metal in your hands for drilling it, if the

drill catches on the metal you will end up with a rather scary saw

blade whizzing around that will cut your hands to ribbons!

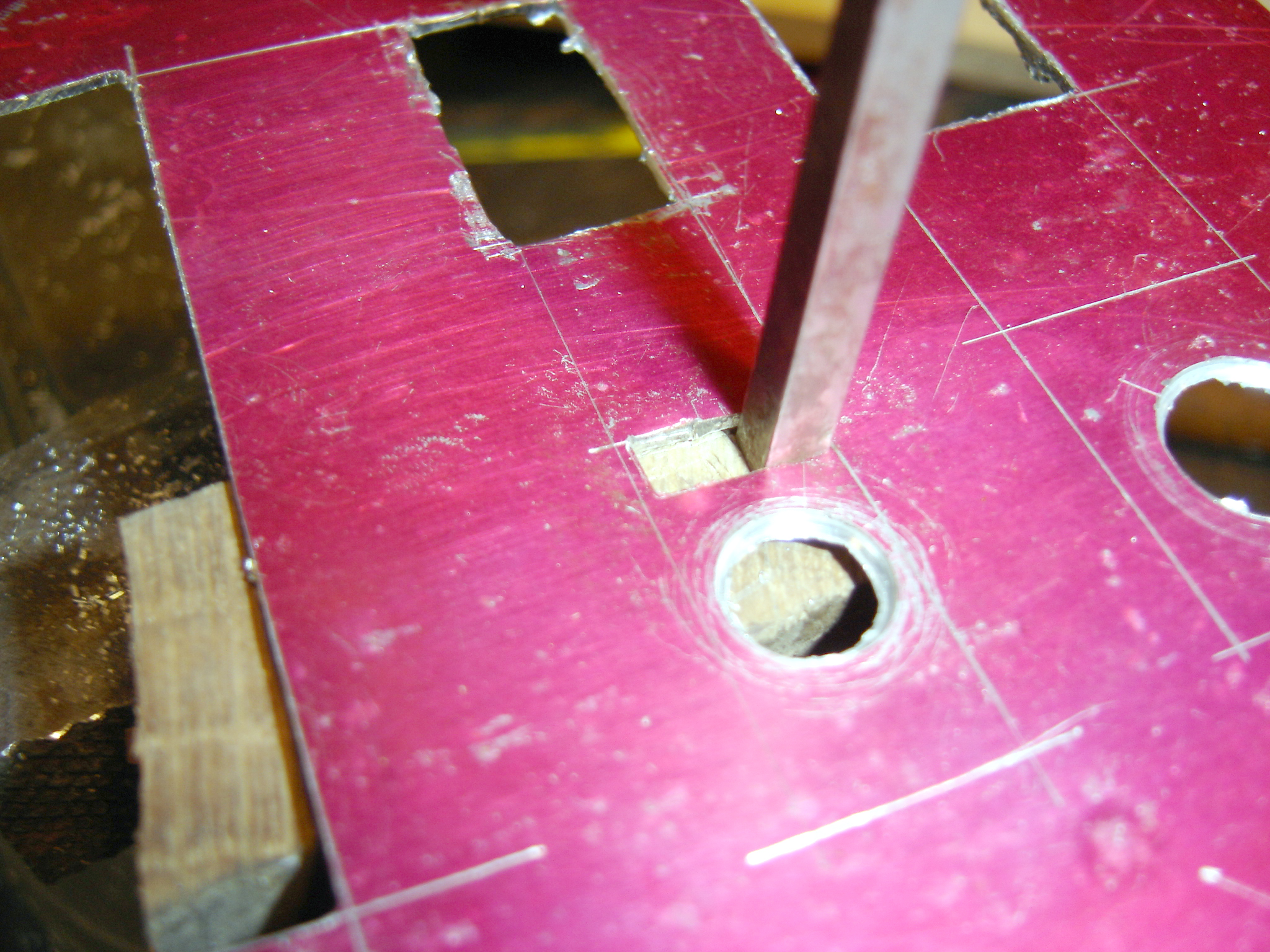

Picture

#4 shows a square file being used to remove the rest of the metal from

the rectangular opening for a switch. This method is surprisingly fast.

5)

Drill a starter hole and use a hand nibbler like the Klein 76011B

Nibbler Tool. The Nibbler tool is a hand operated square punch and die

that closes on the material when the handle is squeezed. They work well

for electronic panels that need small square openings. In use you

"nibble" along the edge staying on the inside of the line. If the

square hole is relatively large you could also use sheet metal hand

shears or an electric or air powered nibbler. Powered sheet metal tools

are relatively expensive but very versatile. Most major manufacturers

make them. Picture #5 shows the nibbler underneath the metal and

Picture #6 shows the cutting head of the nibbler.

Revised for 2019.

Revised for 2019.

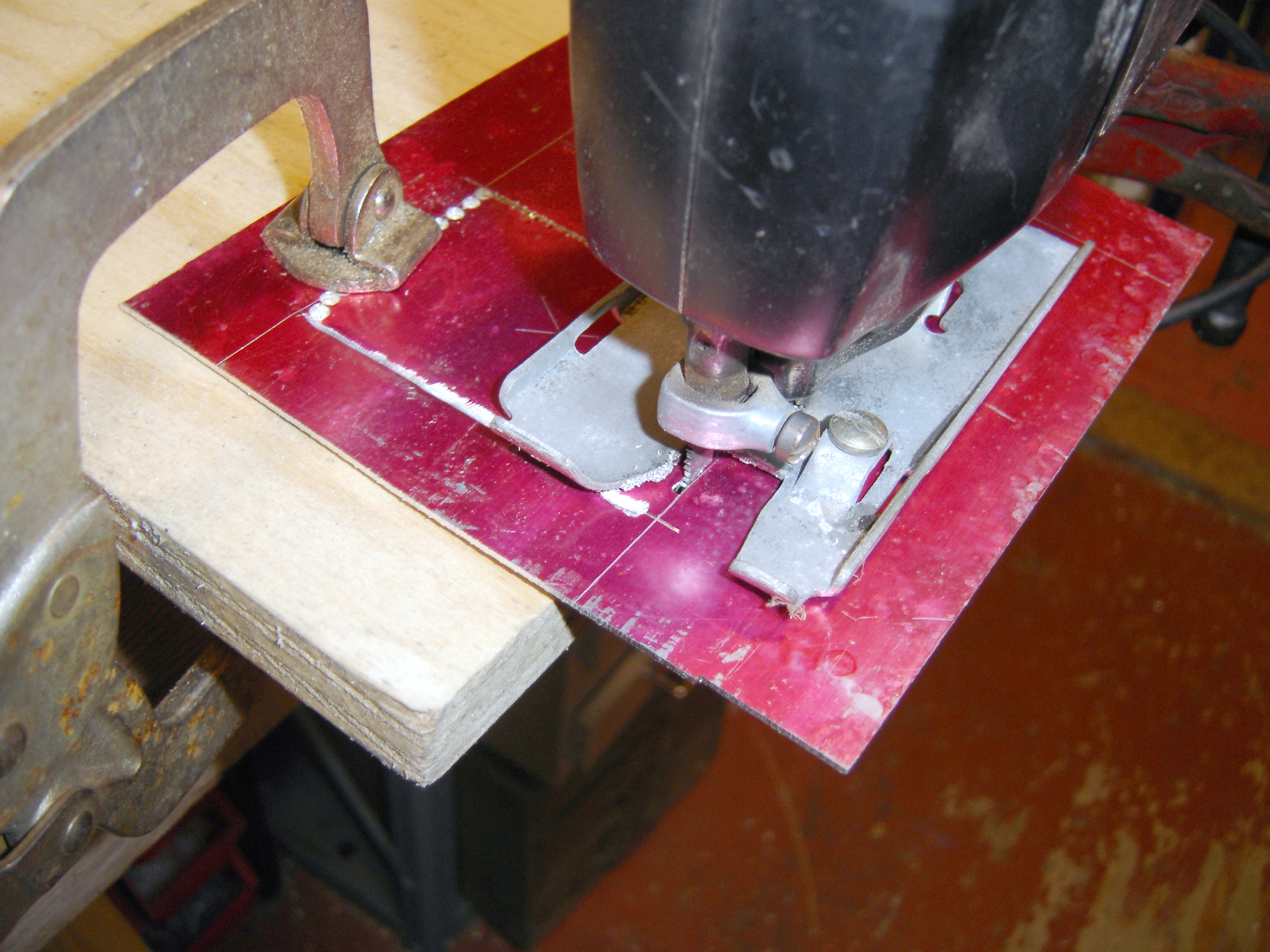

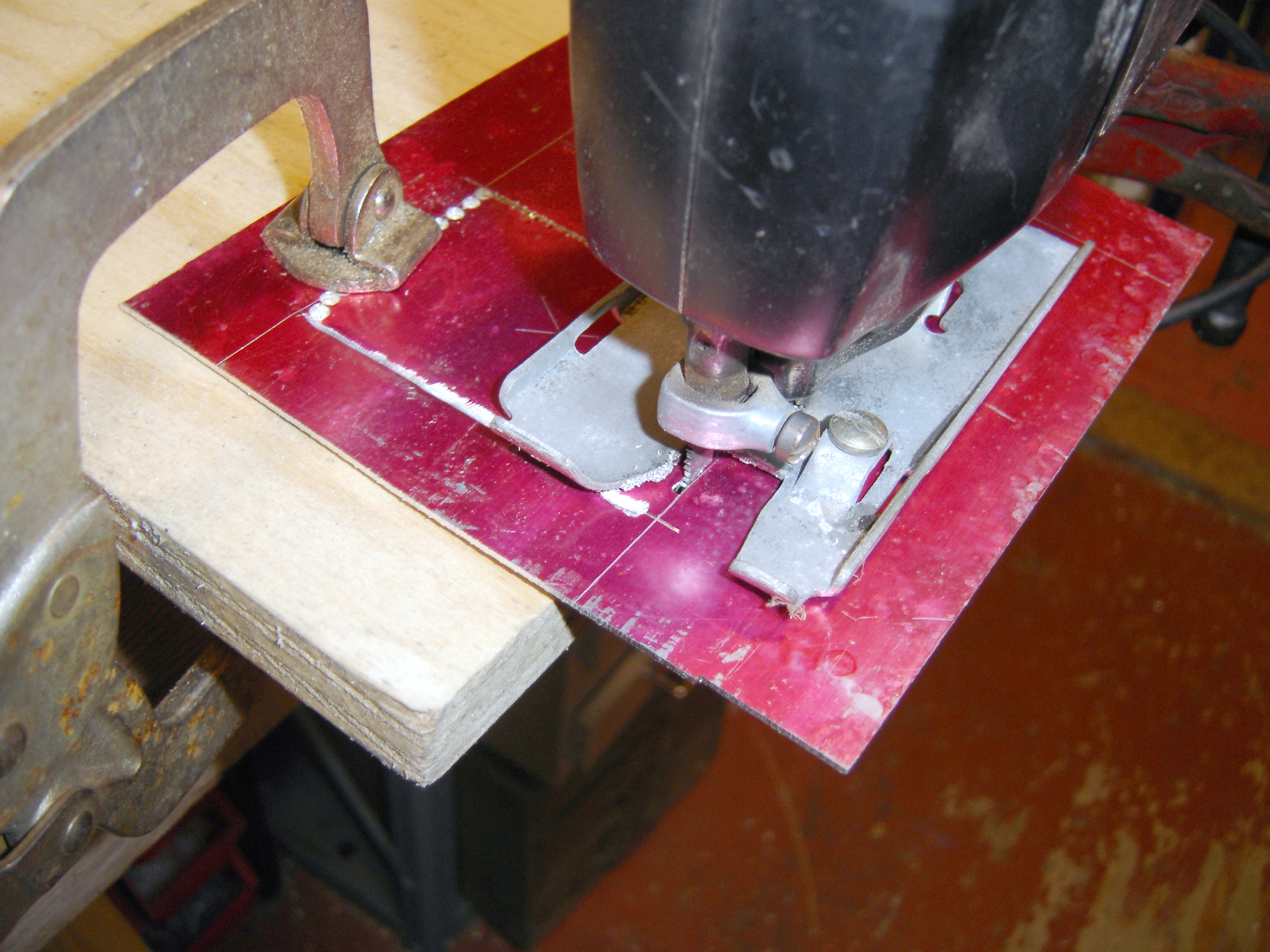

6)

A jigsaw can be used, drill a hole larger than the saw blade and insert

the blade into the opening. Backing the metal edge with some thin

plywood will prevent the metal bending from the force of the blade.

Picture #7 shows a jigsaw cutting the edge of a hole.

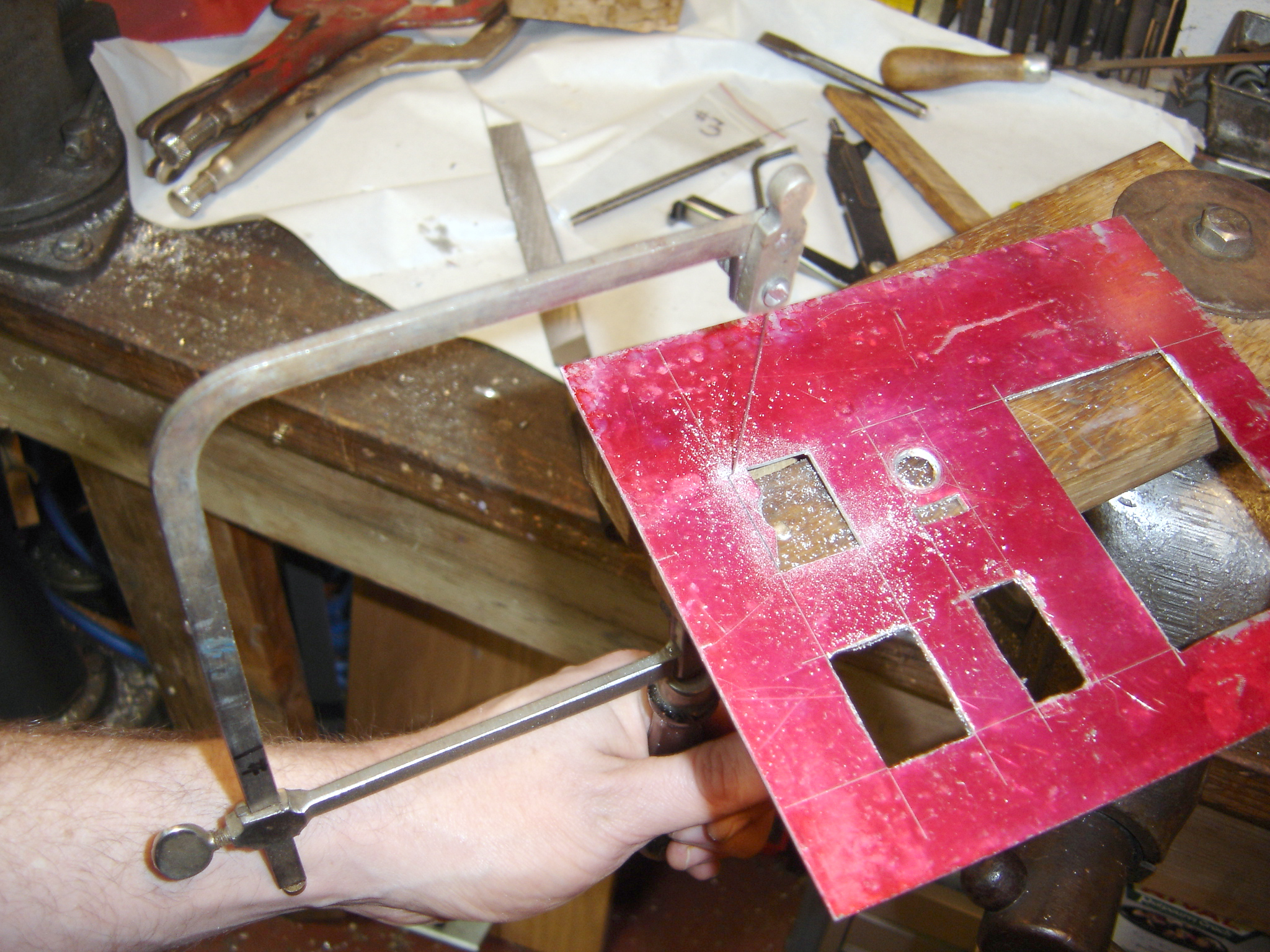

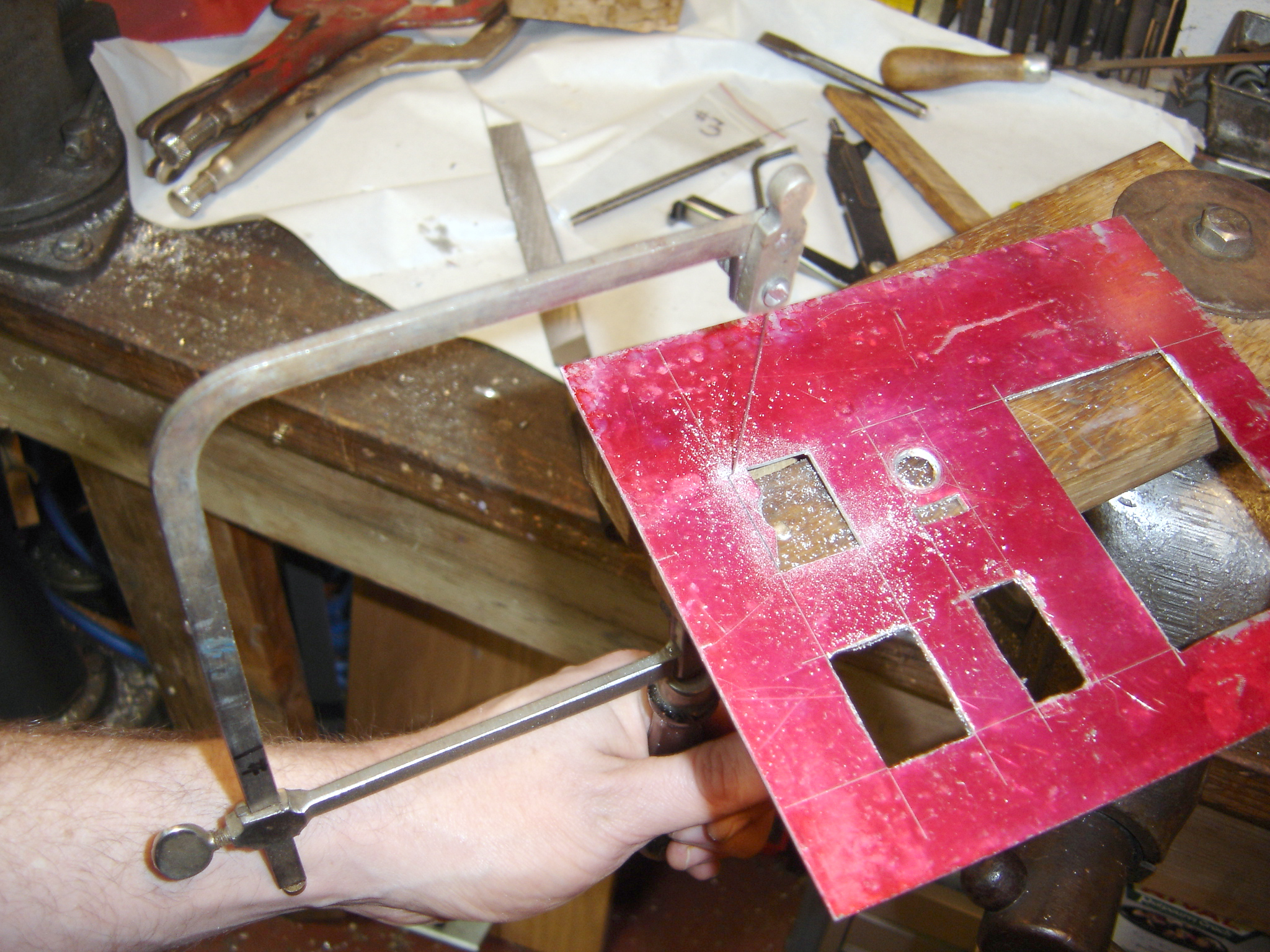

A

jeweler’s handsaw will work quite well for thin metal and small holes.

Use a jeweler’s bench pin to support the work and finish the hole with

files. I had great success with this method as the saw allows great

control and a fine cut. Picture #8 shows the jewelers saw cutting out

the waste from a hole.

You

can do this with a hacksaw if the hole is big enough, holding the work

in a vise as with the hammer and chisel method. Most hacksaw frames

allow the blade to be set 90 degrees from the frame by turning the

blade clamping screws in their square holes. Picture #9 shows the

hacksaw blade set at 90 degrees to the frame, cutting the side of a

hole.

7)

For small holes you can make a square punch from tool steel (available

in many common sizes), harden and temper with a propane torch, then

hammer the punch into the metal, with a piece of endgrain hardwood on

the other side. This does cause some edge distortion. Picture #10 shows

a square punch being used to nibble along the edge of a hole. This

method requires some upper body strength and a big hammer.

8)

Use a Greenlee Knockout die. This is a punch and die set that cut by

sandwiching the metal between the punch and die, screwing them together

with a bolt that passes through the sheet metal. Knockout dies can be

somewhat expensive but they will cut thicker metal than a hand nibbler

and yield a perfect hole. Hydraulic power packs are also available that

increase the speed and force of the punching operation. Picture #11

shows the parts of a Greenlee die and a hole with straight sides and

rounded edges produced with it. Picture #12 shows the punch in use, you

simply tighten up the bolt until the hole is cut. The punches are

available for most standard electronic component shapes besides square

and round holes. They can be very expensive.

10)

If you have access to a manual or CNC milling machine the hole

can be milled, as shown in pictures #13 and #14 of hole for B type USB

female connector, but that will leave radiused corners that

will

still

have to be filed if the part requires it. You can use double sided tape

or the clamping method

I showed for the drill press to clamp the metal to a sacrificial piece

of aluminum, plywood or MDF.

Further possibilities I'm too lazy to demonstrate right now:

10)

You can make a router template jig and use a small router bit to mill

the hole, again leaving radiused corners that will have to be filed.

Cutting wax will prevent the router bit from loading up with aluminum

chips.

11) You can send the work out to a machine shop that

has EDM (electrical discharge machining), laser or abrasive waterjet

capability. Be warned that this can be expensive. CNC punch presses are

becoming more common.

11.1) Some older shops may have a set of

Watts Brothers square hole drills. These are drills that operate on the

principle of the Reuleaux triangle to wobble the bit around the inside

of a template that fits over the metal. These also leave radiused

corners.

11.2) On thicker metal the machine shop may make the

hole using a square broach, which is in essence a square tapered saw

blade that is forced through a round hole, shaving the sides

progressively larger and squarer. Rotary broaches may also be used to

some advantage as well.

12) A plasma cutter can be used if the

edge is to be dressed later with a file, or if a rough edge is

allowable. An oxy acetylene torch can work on steel (but not

aluminum) and will leave very rough edges.

13) You can use a

cutoff disc in a dremel or foredom tool to cut the edges, keep to the

insides of the edges and be aware that it is easy to overshoot the

corners with this method.

14) If you have access to a blacksmith

shop you can "hot punch" a square hole by using a punch made to the

same size as your square hole and heating the metal up in the forge.

This method only works for steel.

15) And finally, redesign the part to use round holes instead of square

ones.

So

you can see that there are many methods that will work, chances are you

have at least one of the tools that will do the job in hand already.

Back to cartertools.com

Copyright Nicholas Carter 2019.

Revised for 2019.

Revised for 2019.